Research conducted by FMJ on behalf of our sister company Metro Rod revealed that businesses that neglect their drainage systems leave themselves significantly at risk of operational downtime. A major part of this risk comes from neglected sewage pumps, an essential asset within the drainage system that pumps the flow of wastewater into the main sewer line.

Research conducted by FMJ on behalf of our sister company Metro Rod revealed that businesses that neglect their drainage systems leave themselves significantly at risk of operational downtime. A major part of this risk comes from neglected sewage pumps, an essential asset within the drainage system that pumps the flow of wastewater into the main sewer line.

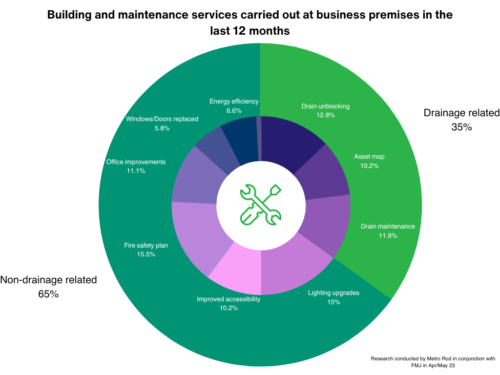

Thousands of businesses across the UK are prioritising office and lighting improvements over drain maintenance, with a staggering 65% of all maintenance services carried out being non-drainage related. This leaves businesses vulnerable to operational downtime – something many say is their biggest challenge today.

The survey delved into challenges faced by businesses across the country, with operational downtime highlighted as one of the most significant concerns, ranking closely behind material shortages. Staff skill shortages, energy price hikes, and rising costs were also prominent concerns for respondents. When asked about what building and maintenance services they’ve carried out over the last 12 months, a considerable portion of respondents reported focusing on non-drainage related activities such as lighting upgrades, office improvements, accessibility improvements and upgrading windows and doors. Surprisingly, less than a quarter have invested in a drainage or asset map – despite nearly a third of businesses reporting blockages in the past year, with a similar percentage incurring drainage costs.

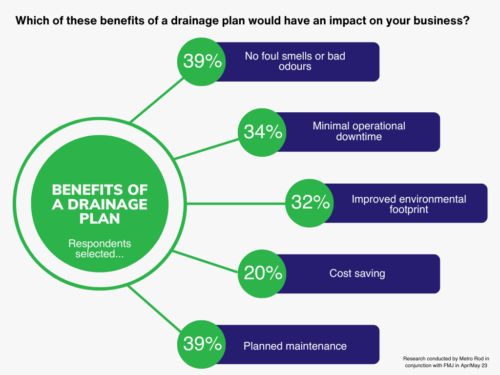

The survey also revealed that respondents recognised the benefits of having a drainage plan in place; identifying benefits such as no foul smells, minimal operational downtime, and an improved environmental footprint. Despite this, only 38% of respondents admit to having a pre-planned maintenance plan (PPM) for their drainage system, leaving almost two thirds of businesses unaware of the condition of their drains. Moreover, many revealed that they only engage with drain maintenance companies in emergencies or when they detect an issue – by this point, the issue could potentially force them to close their doors.

Operational downtime can lead to loss of revenue, poor reviews and damage to your brand reputation. So why, when drainage can have such an impact on business do so many not have a proactive plan in place to ensure their drains function smoothly?

Working in partnership with facilities management providers, we’re encouraging businesses across the UK to invest in pre-planned drain and pump maintenance, so businesses can keep their premises fully operational all year round.

The Benefits of a PPM

PPM’s are a service plan which can be put in place for routine drainage and pump maintenance. It can be scheduled at regular intervals to suit your and your customers’ schedule, such as quiet periods or out of hours. PPM’s are used to prevent scale or grease build-up in pipework, and problems that can lead to bad smells, blocked or overflowing drains and emergency call outs. Ultimately, PPM’s are put in place to help reduce costs and improve operational efficiencies for your business.

Typically, a PPM schedule covers:

- Drain and pipework cleaning

- High-pressure water jetting

- Gully clearance

- Gutter clearance

- Urinal descaling

- Grease trap emptying and cleaning

- Interceptor maintenance

- Sewage pump servicing

Every PPM should be tailored to your site, requirements and budgets, and we would recommend a visit from a drainage engineer every six to twelve months, depending on the facility usage and site conditions.

Sewage Pump Pre-planned Maintenance

A key but often overlooked part of drainage systems is sewage pumps. These are key to ensuring your drainage systems have an adequate flow rate, without them, you could be at risk of backed-up sewage, blockages, and bad smells.

Sewage pump PPM’s are essential to ensure your pump is always in good working order, over time materials like wipes, nappies and sanitary towels will build up in the blades of your pumps as people mistakenly flush them down toilets. Once the blades are caught, this will prevent the pump from working effectively and can even result in a burnt-out pump if not caught soon enough.

PPM’s help to prevent issues with your pump and spot problems before they become an emergency. Helping you to monitor your budget better and prevent emergency pump replacements.

Pollution Prevention

Another key advantage of a pre-planned drain or pump maintenance plan is pollution prevention. With 72% of respondents saying pollution prevention is a priority for their business, it demonstrates the urgency and importance of setting a plan tailored to your business.

Drain and pump maintenance is key to creating a properly functioning drainage system and reducing the risk of contaminants entering the watercourse. A well-executed plan can help with proper waste disposal, such as routine grease collection from grease traps and maintenance of interceptors to prevent blockages causing equipment to fail and pollute the watercourse. A CCTV drain survey can also be used to detect cracks, leaks, and damage, facilitating early action and reducing repair costs. Additionally, they identify misconnections or leaking contaminated waste, contributing to a cleaner environment. Maintenance practices help ensure legislative compliance in addition to safeguarding our environment, a benefit to us all.

With the numerous challenges faced by businesses, operational downtime caused by preventable drainage or pump issues shouldn’t be one of them. Proactive investment in pre-planned maintenance and proper waste disposal practices can mitigate the risk of operational downtime, safeguard the bottom line and prevent pollution.

For more information on pre-planned maintenance, or how to reduce the impact of operational downtime due to drainage or pump issues, please get in touch today and we will be happy to help!