Sewage pumping stations are intermediate storage chambers that collect sewage, effluent, or surface water. These collection chambers incorporate automatic control systems that operate the pumps and the pumps transfer surface water or wastewater to the nearest sewer or manhole.

Pumps are used to lift and distribute sewage and wastewater when gravity will not naturally direct it away from the location. This may be in areas where the main sewer is located on higher ground than the receiver for sewage. Pump stations may also be needed when the sewer passes over an incline or where the volume of waste is significant enough that the system might be overloaded.

Pump stations are used across many applications, including residential homes, housing developments, commercial developments, industrial estates, campsites, schools, and healthcare premises.

Pump stations offer a wide range of benefits, including convenience when installing a sewage system and lowering construction costs. They are available in a wide range of types and sizes and can be fitted with remote operating systems to keep managers updated, and some are fitted with alarms to alert you if something goes wrong.

How does a pump station work?

Sewage is collected and stored in a chamber called a wet well or tank from a house or group of houses or buildings. When this reaches a specific level, it will activate the float switches set at a predetermined level. This will switch on the pump, pushing the wastewater out of the wet well and uphill into the main sewer line. From here, it will travel using gravity to the main sewer.

There is no need to switch it on and off manually. Once the wastewater level has fallen below a certain point, the pump will stop working. A non-return valve is built into the pump station to ensure that wastewater cannot flow back into the wet well.

How do you know the right pump station for your application?

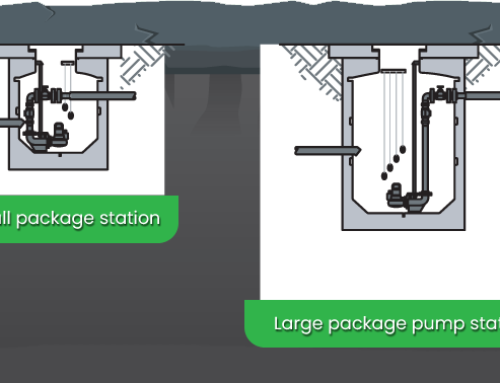

There are different types of pump station systems, and the right one for you will depend on various factors, including the size and type of development, the heights and distance between the proposed pump station location and the rising main, and the requirement of 24-hour storage to comply with current building regulations.

Most pumps come in both single and dual pump formats. Dual pump formats allow larger premises to increase capacity but also offer back up if one pump fails for any reason. Our team can advise you about the right pump station for your application and source and install it.

What else is important to know?

Pump stations will only work well if they are regularly maintained. Given the harsh environment in which they work, regular maintenance is essential to reduce the risk of pump station breakdowns.

We provide regular pump station maintenance for all types of pumps, including cleaning the pump, testing all equipment, and checking the power supply and float switches. We will also check all rotation parts and other electrical components, including the operating lubricants.

Want to find out more about ump stations and our pump station services? Call now

Would you like to know more? Our pump station specialists can be reached on 01634 201 111 or via email at service@willowpumps.co.uk

We complete all pump station maintenance in Kent.